WHAT IS CE MARKING

Ce Marking is a health and safety symbol, which is implemented within the framework of “New Approach” constituted by European Union (EU) in 1985, so as to ensure free movement of goods. It was intended that, instead of various conformity symbols used in throughout EU, a unique EU symbol be used which designates conformity with the directives. CE Marking is the symbol of conformity with the EU New Approach Directives, which shows that the product on which it has been affixed is healthy and safe for the purposes of people, domestic animals and environment. It is not possible for a product within the scope of one or one or two New Approach Directives, the number of which is now 25, to be put on the EU market without bearing CE Marking. It is of basic importance that the manufacturers manufacture conformable to the harmonised standards involving directives in proving the conformity with the New Approach Directives. Even if conforming to the standards is not mandatory, in case of manufacturing conformable to the standards, the presumption of conformity with the directives stimulates the manufacturer to conform to the standards.

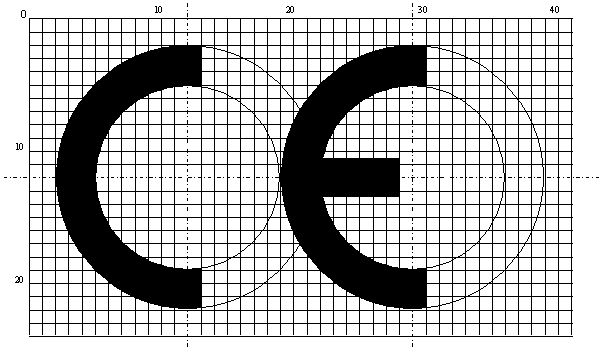

CE Marking is not a quality mark. It means the product on which it has been affixed meets all the requirements of the related directive and appears so as to ensure free movement of goods among the Member States of the EU.CE Marking of conformity consists of the capital letters in the form of the figure below. If CE Marking of conformity is minimised or enlarged it must be fit in with the ratios given above.

Please click for our Notified Body scope.

WHICH PRODUCTS MUST BE CE MARKING?

- Products within the scope of the directives involving CE Marking given in the following table,

- All new products which have been manufactured in the Member States and in third countries,

- Second-hand products imported from third countries,

- Products subject to the provisions of the directives as if new products and products which have undergone a change significantly must bear CE Marking.

PROCEDURES OF AFFIXING CE MARKING;

Directive(s) involving the product is/are determined.

(If exist) Harmonised Standards are identified.

Module or combination of modules is/are selected.

Whether Notified Body is required or not is determined.

Subsequent to conformity assessment, declaration of conformity and if required other documents are prepared.

Technical file is prepared and retained.

“CE” Marking is affixed to the product and/or on its package and on the accompanying certificate and the product is put on the market.

IMPROPER USE OF CE MARKING

In case a situation in non-conformity with the directives is ascertained, the manufacturer or its authorised representative is obliged to ensure that the product is in conformity with the provisions involving CE Marking of conformity and bring the violation to a close. In case the non-conformity continues, the Ministry, in the framework of the authority given by Law, takes all the appropriate measures to restrict or prohibit those products being placed on the market or to withdraw them from the market.

NEW APPROACH AND MODULAR SYSTEM

In the “New Approach”, directives don’t include too much technical detail, but they designate the general principles that the manufactured products must be in conformity with according to the product groups. Besides, the products meeting the “Essential Requirements” are ensured to be in free movement.

Directives are arranged not according to the products but according to the intended use of the products. Consequently, the products functioning similarly are gathered together in groups and “minimum safety requirements” are determined by means of only one directive.

A modular conception has been implemented in CE Marking system since 1990. The main objective of the modular concept is to determine the conformity assessment procedures by taking the product characteristics and their risk level into consideration.

When the Construction Products Directive is in question, product’s meeting the “Essential Requirements” of the New Approach Directives is implemented by its fulfilling the conditions of the Annex ZA of the harmonised standards.market.

In the Construction Products Regulation there is an approach named as “Assessment and Verification of Constancy of Performance” instead of Modular approach.

Assessment And Verification Of Constancy Of Performance

SYSTEM 1+ / 1

Declaration of the performance of the essential characteristics of the construction product by the manufacturer on the basis of the following items:

(a) The manufacturer shall carry out:

1.Factory production control (FPC)

2.Further testing of samples taken at the factory in accordance with the prescribed test plan

(b) The notified product certification body shall issue the certificate of constancy of performance of the product on the basis of:

1.determination of the product-type on the basis of type testing (including sampling), type calculation, tabulated values or descriptive documentation of the product;

2.initial inspection of the manufacturing plant and of factory production control

3.continuous surveillance, assessment and evaluation of factory production control

4.audit-testing of samples taken before placing the product on the market (only for 1+)

SYSTEM 2+

Declaration of the performance of the essential characteristics of the construction product by the manufacturer on the basis of the following items:

(a) The manufacturer shall carry out:

1.Factory production control (FPC)

2.testing of samples taken at the factory in accordance with the prescribed test plan

3.determination of the product-type on the basis of type testing (including sampling), type calculation, tabulated values or descriptive documentation of the product

(b) The notified production control certification body shall issue the certificate of conformity of the factory production control on the basis of :

1.initial inspection of the manufacturing plant and of factory production control

2.continuous surveillance, assessment and evaluation of factory production control

SYSTEM 3

Declaration of the performance of the essential characteristics of the construction product by the manufacturer on the basis of the following items

(a) The manufacturer shall carry out: Factory production control (FPC)

(b) The notified testing laboratory shall carry out determination of the product-type on the basis of type testing (based on sampling carried out by the manufacturer), type calculation, tabulated values or descriptive documentation of the product

SYSTEM 4

Declaration of the performance of the essential characteristics of the construction product by the manufacturer on the basis of the following items

(a) The manufacturer shall carry out:

1. factory production control (FPC)

2. determination of the product-type on the basis of type testing, type calculation, tabulated values or descriptive documentation of the product

(b) No tasks for the notified body

CONFORMITY ASSESSMENT MODULES

1. Module A: Internal Production Control

2. Module B: Type Examination

3. Module C: Conformity to Type

4. Module D: Production Quality Assurance

5. Module E: Product Quality Assurance

6. Module F: Product Verification

7. Module G: Unit Verification

8. Module H: Full Quality Assurance

Module A: Internal Production Control

This module covers internal design and production control. The manufacturer declares the conformity of the product with the relevant directives and prepares a technical file which explains the design, production and usage of the product. This module does not require a Notified Body to take action.

Module B: EC Type Examination

This module, covering only the design phase, is generally used together with a declaration of conformity. Within the framework of this module, for which CE Marking is not stipulated, Notified Body tests the product type to the relevant directive.

Module C: Conformity to Type

This module, covering the production phase, is not sufficient alone. It represents a phase after EC Type Examination Module (Module B). As a result of this module, which is used to show the conformity of the product with the requirements of the directive, the manufacturer affixes CE marking to the product and draws up a declaration of conformity.

Module D: Production Quality Assurance

This module covers the production phase and follows Module B. It involves testing and approval processes carried out by a Notified Body. The process it pursuits is similar to the production, foundation and after sales service scope of ISO 9000 (ex. ISO 9002). It envisages a quality assurance system to be established oriented to production. Final product inspection and testing are implemented by the manufacturer.

Module E: Product Quality Assurance

This module covers the production phase and follows Module B. It involves testing and approval processes carried out by a Notified Body. The process it pursuits is similar to the final check and tests, purchasing + packaging + after sales services (does not involve production) scope of ISO 9000 (ex. ISO 9003). It envisages a quality assurance system to be established oriented to production. Final product inspection and testing are implemented by the manufacturer.

Module F: Product Verification

This module is oriented to only production phase and is used together with Module B. A Notified Body controls the product’s conformity to type and technical documents. Within the framework of this module CE Marking is affixed accompanying a certificate of conformity.

Module G: Unit Verification

This module covers the design and production phases. Each individual product is examined by a Notified Body, which issues a certificate of conformity. As a result of this module CE Marking is affixed to the product.

Module H: Full Quality Assurance

This module, involving design and production phases, is implemented by a Notified Body’s control of quality management system (ISO 9000’s scope of design + development + production + foundation + after sales services). In case the design does not conform to the harmonised standards fully, it is controlled whether the design conforms to the provisions of the directive or not.

CE MARKING

CE Marking is a mark of conformity with the New Approach Directives of the EU which shows the product on which it has been affixed is safe for the purposes of environment. A product might be in the scope of more than one directive and the CE Mark affixed to the product by fulfilling the necessary requirements shows that the product is in conformity with all those directives. Conformity with the directive means meeting the essential requirements of the directive by pursuing the conformity assessment procedures specified in the directive. These essential requirements foresee the terms related to the product safety. Nevertheless, essential requirements do not indicate the terms related to the product’s performance characteristics and quality directly. Consequently CE Marking is related to the safety of the products and it aims essentially free movement of goods within the EU.

Consequently, product certification should be appraised as an alternative for CE Marking. The continuous increase in the product certification activities other than CE Marking in all of the EU countries is the most obvious indication of this.

WHAT IS THE RELATIONSHIP BETWEEN CE MARKING AND QUALITY MANAGEMENT SYSTEM ?

CE Marking does not have a direct relationship with the Quality Management Systems ( ISO 9001). CE Marking symbolizes that a product has been designed and manufactured in conformity with the New Approach Directives of EU and relevant Harmonised European Standards. It is seen that in modular system Quality Management Systems are stipulated for some product groups.